Associate Functional Solution Architect

Subscribe to the newsletter

In Part 1 of this guide, we walked through the foundational steps for setting up catch weight products or warehouse management processes. Now, let’s dive deeper into how these settings come into play within the sales and purchase order processes. Understanding how to effectively handle catch weight management during these transactions is crucial for accurate inventory management, pricing, and order fulfillment.

Let’s explore the key steps for working with catch weight items when creating and processing sales and purchase orders in Dynamics 365 for Finance & Operations.

How to create a purchase order process with catch weight items?

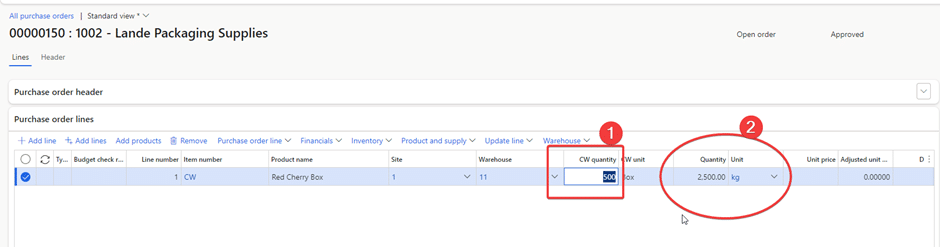

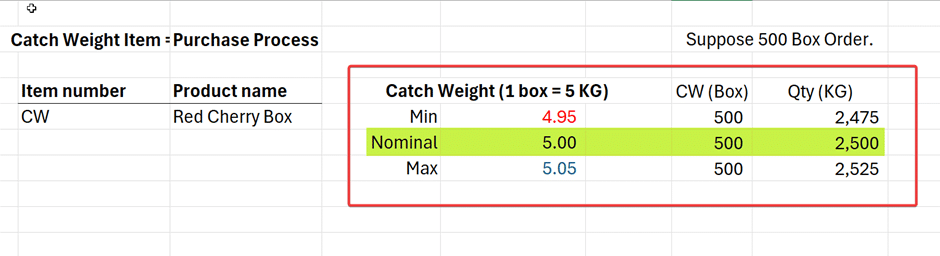

Creating purchase order lines for catch weight items involves distinct processes compared to standard purchase orders. For example, purchasing 500 boxes, equivalent to 2500 kg based on the defined unit conversion, highlights key differences:

- In a catch weight purchase order, the “Quantity” field in Inventory is disabled (greyed out).

- The “Catch Weight Quantity” field remains active and editable.

Purchase order quantity registration

When registering quantities in a Purchase Order for catch weight products, users can enter both the Catch Weight Quantity and the Inventory Quantity. However, the system enforces limits based on the catch weight setup:

- For 500 boxes, the total Catch Weight Quantity must be between 2475 kg (minimum) and 2525 kg (maximum).

- If the entered quantity falls outside this range, the system will display an error message.

Handling quantity validation scenarios in catch weight orders

Let’s walk you through three scenarios to verify the system’s behaviour and check for any errors.

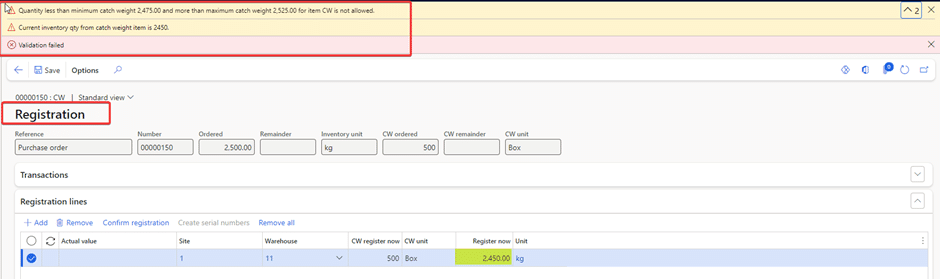

Test Case 1: Entering quantity below minimum interval

Scenario

Enter a quantity of 2450 kg for 500 boxes, which is below the defined minimum interval (2475 kg).

Expected behavior

- Quantity less than minimum catch weight 2,475.00 and more than maximum catch weight 2,525.00 for item CW is not allowed.

- Current inventory quantity for the catch weight item: 2450 kg.

- Validation failed.

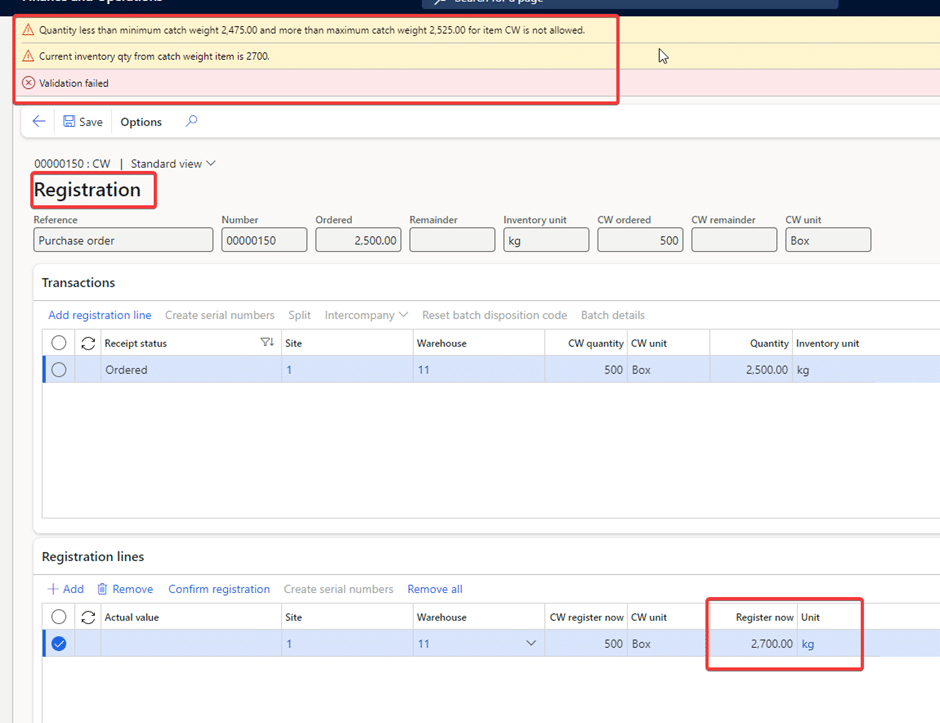

Test Case 2: Entering quantity above maximum interval

Scenario

Enter a quantity of 2700 kg for 500 boxes, which exceeds the defined maximum interval (2525 kg).

Expected behavior

- Quantity less than the minimum catch weight of 2,475.00 and more than the maximum catch weight of 2,525.00 for item CW is not allowed.

- Current inventory quantity for the catch weight item: 2700 kg.

- Validation failed.

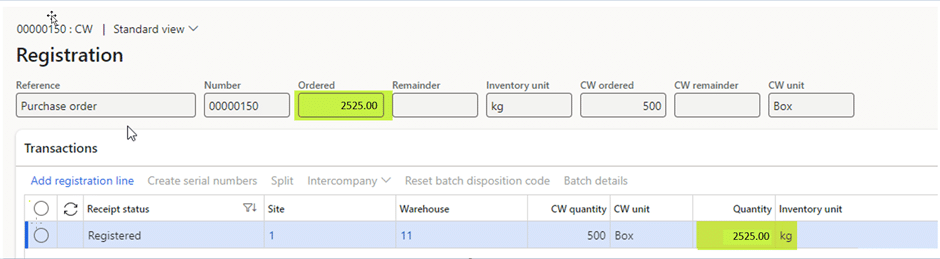

Test case 3: Entering quantity within the interval

Scenario

Enter a quantity of 2525 kg for 500 boxes (within the defined range).

Outcome

- Quantity successfully registered.

- Inventory reflects 500 boxes with a recorded quantity of 2525 kg.

Important considerations for partial product receipt and invoice

The Inventory Quantity (KG) cannot be updated when creating a partial or full product receipt or invoice. Adjustments can only be made during quantity registration.

The Catch Weight Quantity (boxes) can be updated and adjusted as required for partial receipts.

Partial product receipts and invoices can be posted for catch weight items, but the inventory quantity (KG) will adjust automatically based on the Catch Weight Quantity.

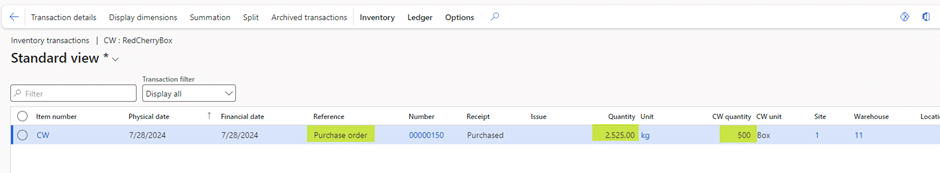

Purchase inventory transactions

In the purchase inventory transaction, the following details will be observed:

- Catch weight: The transaction records 500 boxes of the product purchased.

- Inventory quantity: The corresponding inventory quantity recorded is 2525 kg.

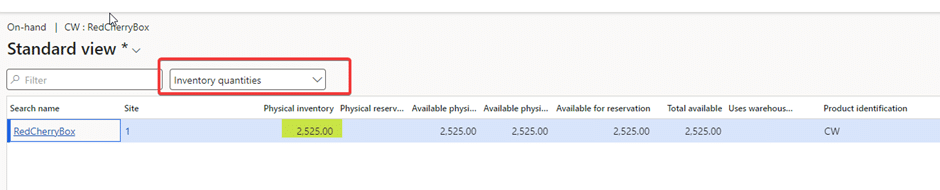

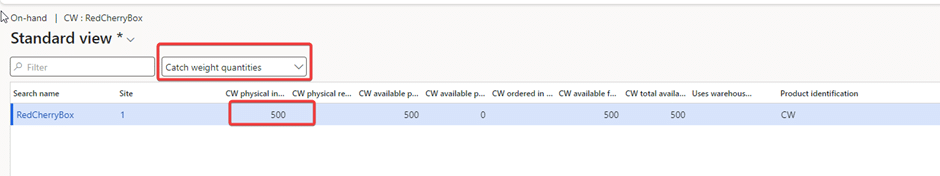

Catch weight on-hand inventory

The on-hand inventory reflects both the total weight and the number of boxes for the catch weight product, ensuring accurate inventory tracking:

- Inventory quantity: 2525 kg

- Catch weight quantities: 500

This dual tracking allows for effective inventory management and ensures precise monitoring of both item quantities and their associated weights.

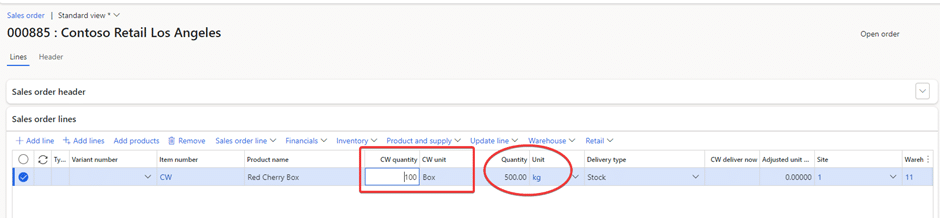

How to create a sales order process with catch weight items?

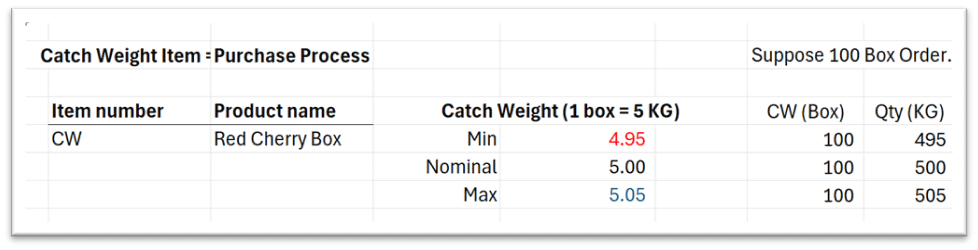

In this section, we will create sales order lines for catch weight items and proceed to invoicing. For example, if we are selling 100 boxes, this equates to 500 kg based on the defined unit conversion.

In a standard sales order, the “Quantity” field in Inventory remains editable. In a catch weight sales order, the “Quantity” field is disabled (greyed out), while the “Catch Weight Quantity” field remains active and editable.

How to pick quantity in sales order for catch weight products?

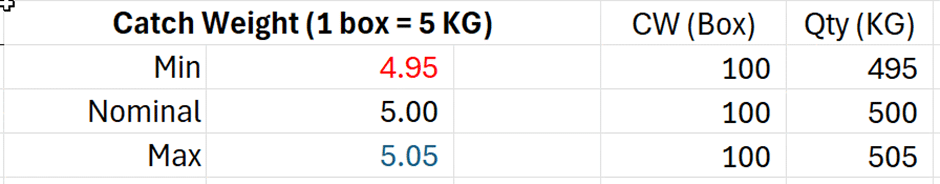

When picking quantities in a Sales Order for catch weight products, users can enter both the Catch Weight Quantity and the Inventory Quantity. However, the system enforces limits based on the catch weight setup:

- For 100 boxes, the Catch Weight Quantity must fall between 495 kg (minimum) and 505 kg (maximum).

- If the entered quantity falls outside this range, the system will display an error message.

These limits are defined in the Catch Weight setup to ensure that inventory quantities remain within acceptable bounds.

Sales order picking: Quantity validation scenarios

Let’s walk you the three scenarios to verify the system’s behaviour and check for any errors.

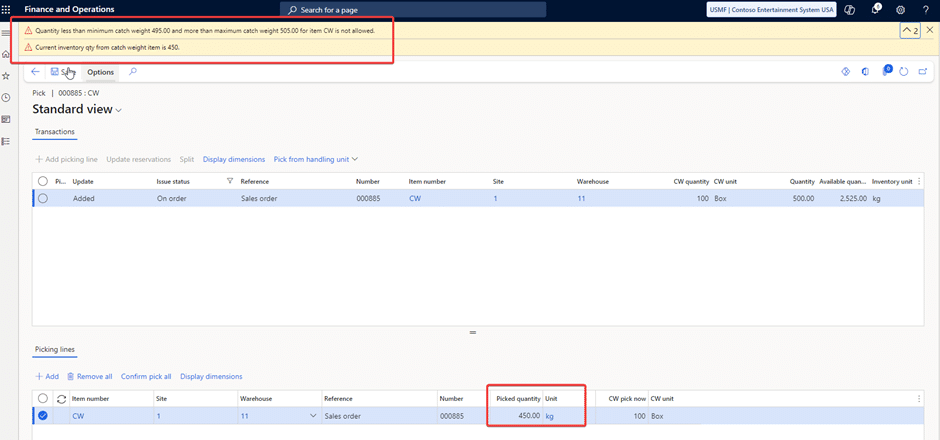

Test case 1: Entering quantity below minimum interval

Scenario

Enter a quantity of 450 kg for 100 boxes, which is below the minimum interval of 495 kg.

Expected outcome

The system should display an error message and reject the entry.

- Quantity less than minimum catch weight 495.00 and more than maximum catch weight 505.00 for item CW is not allowed.

- Current inventory quantity for catch weight item: 450 kg.

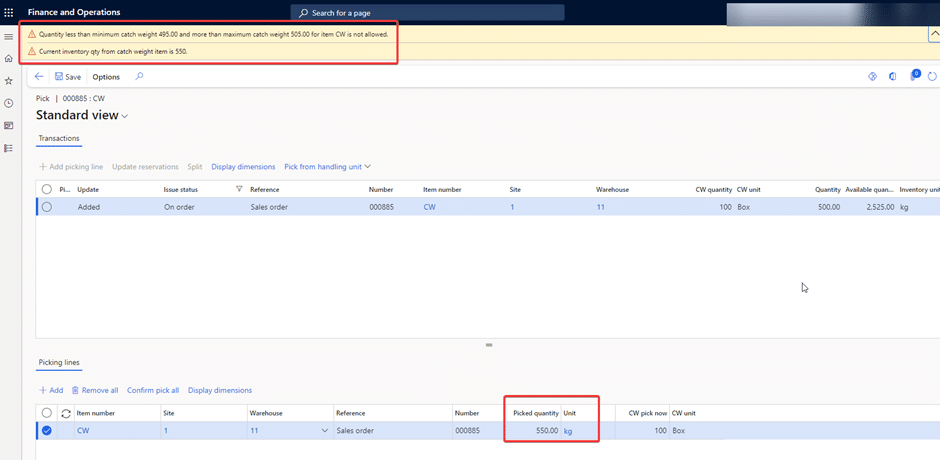

Test case 2: Entering quantity above maximum interval

Scenario

Enter a quantity of 550 kg for 100 boxes, which is above the maximum interval of 505 kg.

Expected outcome

The system should display an error message and reject the entry.

- Quantity less than minimum catch weight 495.00 and more than maximum catch weight 505.00 for item CW is not allowed.

- Current inventory quantity for catch weight item: 550 kg.

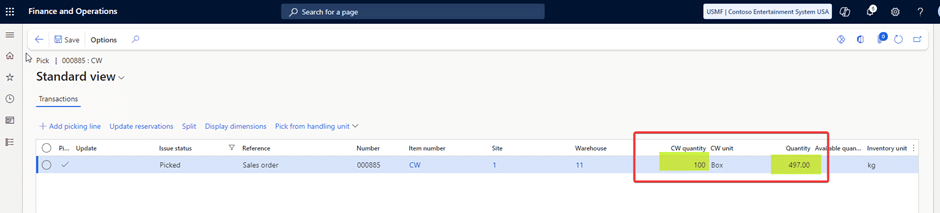

Test case 3: Entering quantity between the min and maximum

Scenario

Enter a quantity of 497 kg for 100 boxes, which falls within the defined range of 495 kg to 505 kg.

Expected outcome

The system should accept the entry and successfully pick the quantity.

Result

- Quantity Picked: 497 kg

- Boxes Picked: 100

The inventory reflects the updated quantities without any errors.

Important considerations for partial packing slip and invoice

The Inventory Quantity (KG) cannot be updated while creating the partial or full product receipt or invoice; it can be adjusted at the time of quantity registration.

The Catch Weight Quantity (box) can be updated and adjusted as required Partial. This means we can post the partial product receipt and invoice of catch weight items, but we cannot update the inventory quantity (KG) it will adjust automatically as per CW quantity.

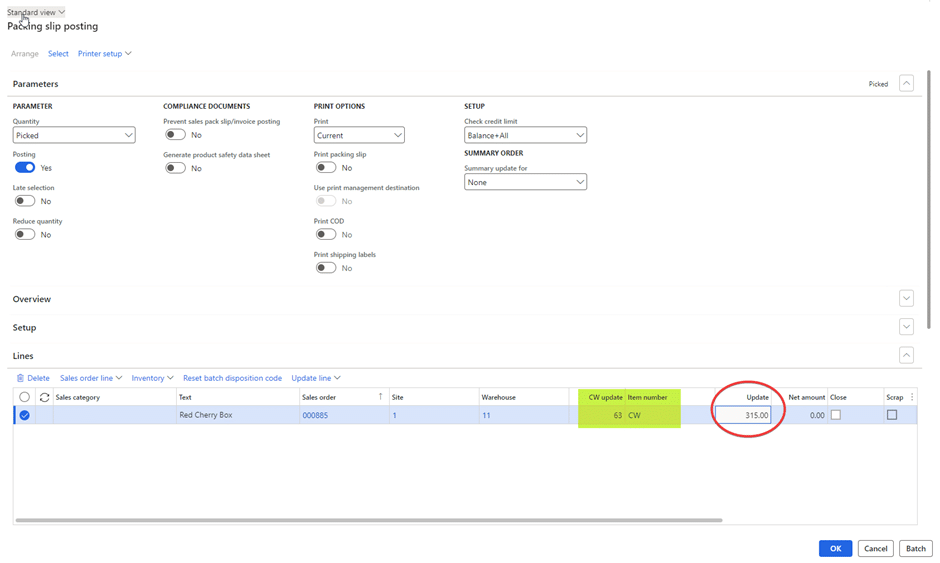

Posting packing slip

Partial Quantity Posted: 63 boxes

Inventory Quantity Updated: 315 kg

Explanation

- Partial quantity: When we post a packing slip for the catch weight product 63 boxes recorded as a partial quantity.

- Automatic inventory update: The system automatically updates the inventory quantity based on the catch weight quantity. For 63 boxes, the inventory quantity is updated to reflect a total of 315 kg.

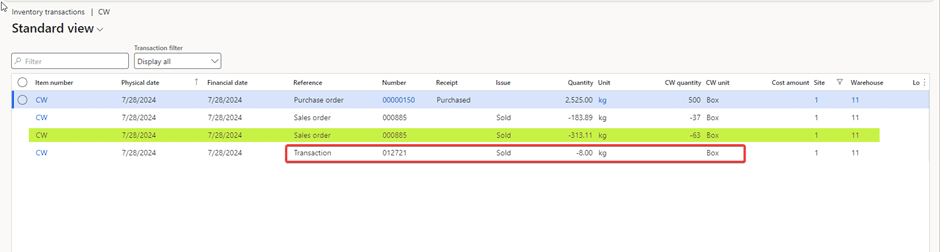

Sale inventory transactions

In this inventory transaction, we will see that:

- Catch Weight: The transaction indicates that 63 boxes of the product were purchased.

- Inventory Quantity: The recorded inventory quantity for these boxes is 313.11 kg remaining 8 kg in conversion will be posted as adjust transaction whose reference document type is “Transaction”.

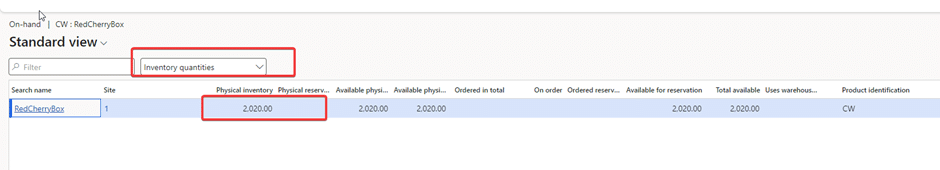

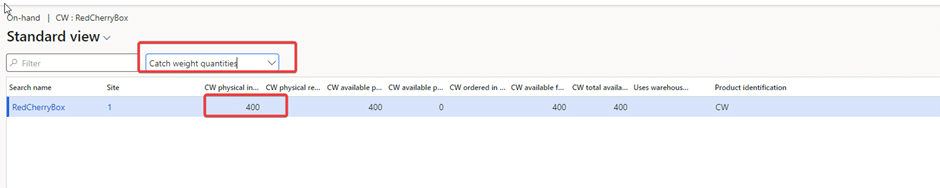

Catch weight item on hand inventory

The on-hand inventory displays both the total weight and the number of boxes for the catch weight product. This allows for effective inventory management and ensures accurate tracking of both the quantity of items and their corresponding weights.

Inventories Quantities: (2020 kg)

Catch Weight Quantities: (400 boxes)

Summing up

Managing Catch Weight items in Dynamics 365 Finance & Operations goes beyond simple inventory tracking. By understanding and effectively implementing processes for purchase and sales orders, businesses can ensure accuracy, compliance, and operational efficiency.

With the insights and steps outlined in this guide, you can streamline operations, enhance inventory management, and unlock the full potential of Catch Weight functionality in your organization. Need more assistance? Reach out to us at marketing@confiz.com and take the next step toward efficient catch weight handling with our experts today!