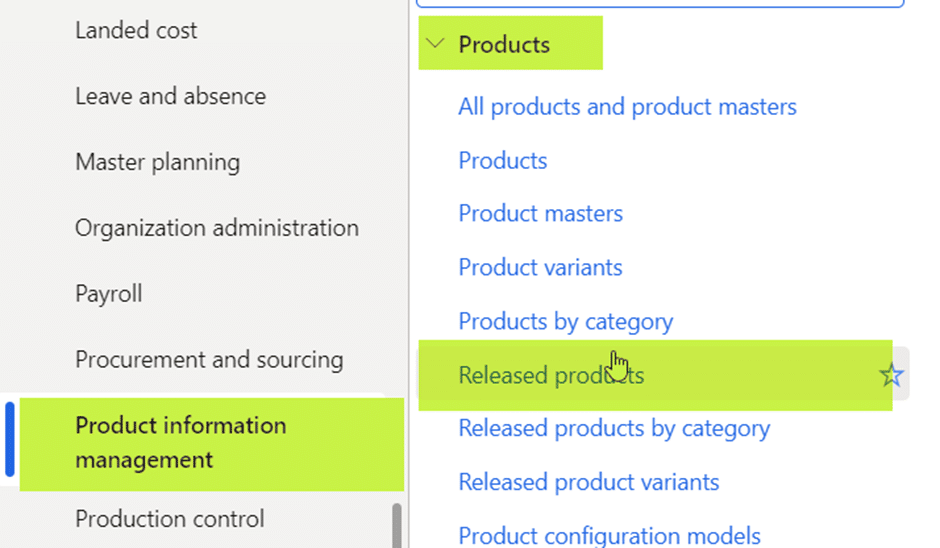

Managing products with varying weights or sizes can be a logistical nightmare for businesses across multiple industries. That’s where catch weight (CW) functionality in Microsoft Dynamics 365 Finance and Operations (F&O) comes in, providing a solution tailored to streamline inventory processes and ensure precision. Whether you’re working with bulk goods or manufacturing components, the ability to manage dual-unit measurements can significantly enhance the accuracy and efficiency of tracking inventory, sales, and procurement.

In this blog, we will explore the concept of catch weight management in Dynamics 365 for Finance & Operations, discuss its setup and configuration, and walk you through its practical limitations.

What is the catch weight in warehouse management?

In Dynamics 365 Finance and Operations (F&O), Catch Weight (CW) functionality is designed to manage products that vary in weight or size, such as food products or other bulk items. When it comes to catch weight meaning, it refers to a method of managing inventory for products whose weight varies slightly from unit to unit, even though they are sold by a standard unit count. It is commonly used in industries like food, agriculture, and manufacturing, where items such as meat, produce, or chemicals have variable weights.

Catch weight (CW) products use two types of measurements:

- Inventory unit

The inventory unit is the unit of measure that tells how the product is weighed and billed. For example, kg, lb, or oz.

- Catch weight unit

The catch weight unit is the unit that is used for managing the product during transactions, such as when it’s sold, received, moved, or shipped. This could be in boxes or pieces. So, while the product might be billed by weight, it’s managed in terms of boxes or pieces.

Examples of catch weight unit

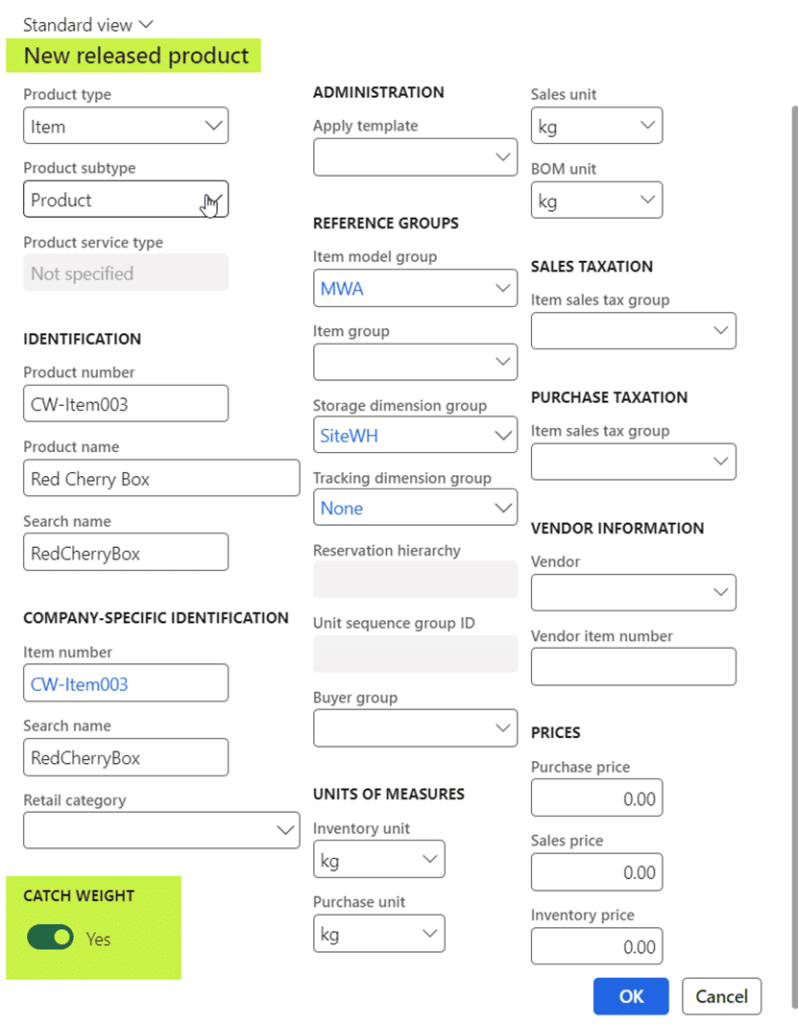

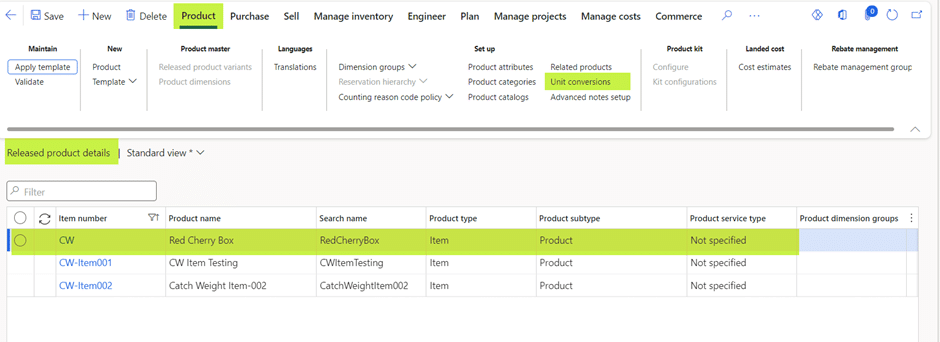

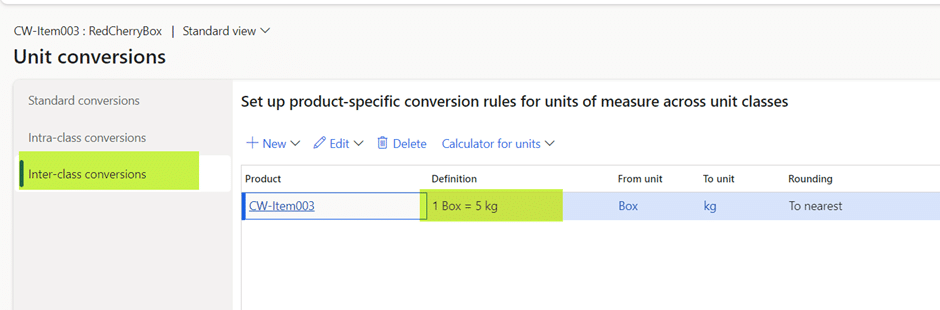

Suppose we have cherries packed in boxes, with each box varying in weight. Although the cherries are invoiced by weight in kilograms (KG), they are sold in boxes. When a customer orders cherry boxes, the boxes are weighed to determine the total weight for invoicing.

In this scenario, we use kilograms (KG) as the inventory unit and boxes as the catch weight unit. This means that while the inventory is tracked in kilograms, the sale is processed based on the weight of the boxes.

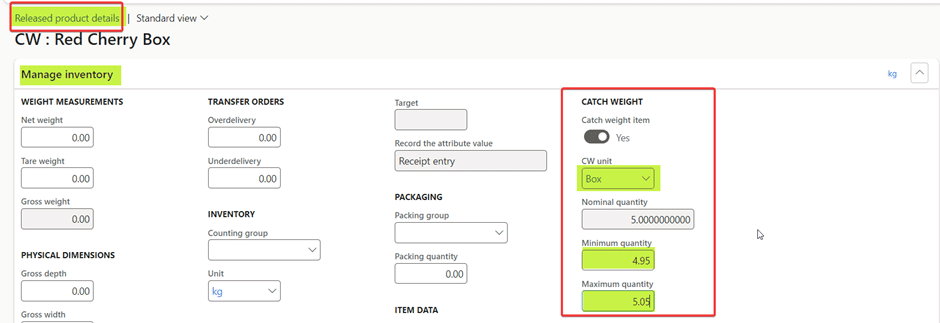

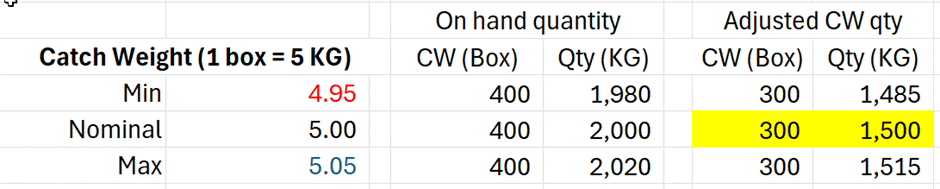

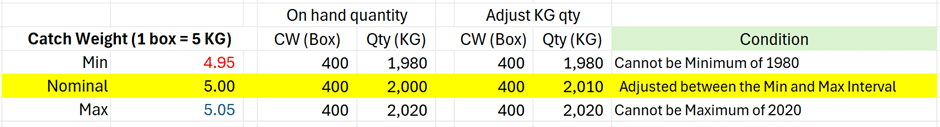

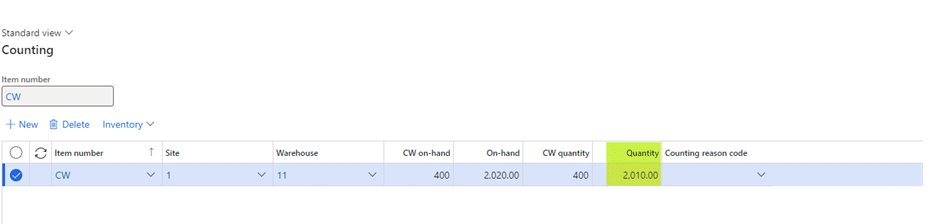

What are the different types of catch weight quantities?

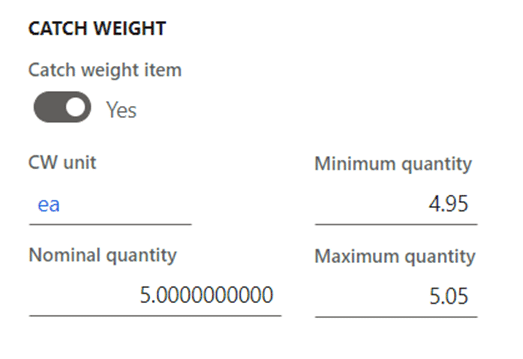

Catch weight (CW) involves three types of quantities: Nominal, Minimum, and Maximum. Together, these quantities help manage and regulate inventory in both the catch weight unit and the standard inventory unit.

- Nominal quantity

This defines the conversion rate between the catch weight unit and the inventory unit. For example, if the nominal quantity is set to 5 kilograms (KG) per box (each), then 1 box is equivalent to 5 kilograms.

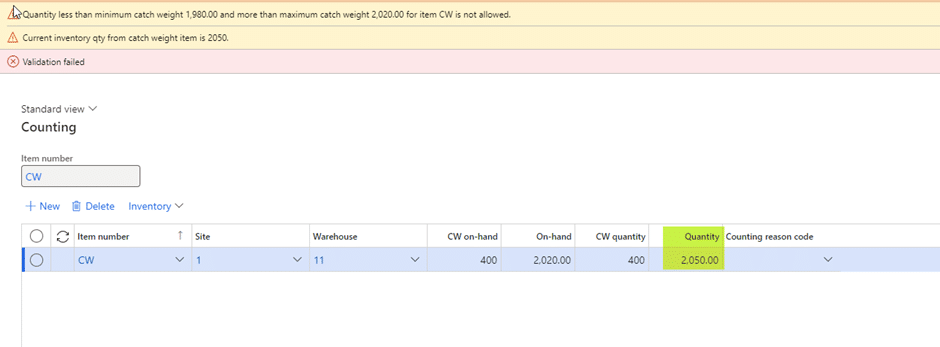

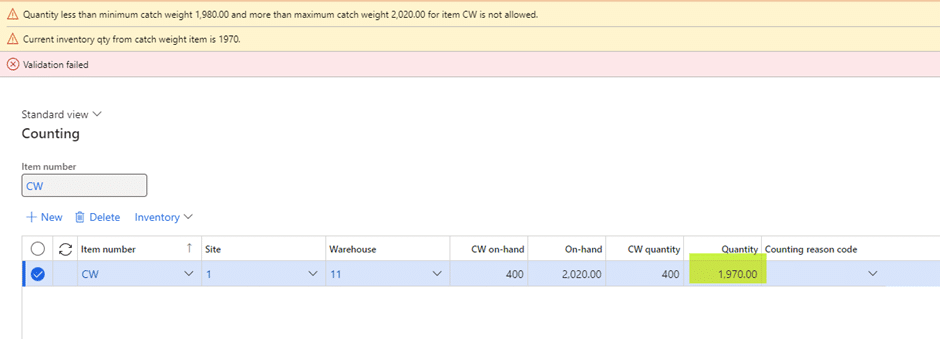

- Minimum quantity

This specifies the minimum allowable quantity in the inventory unit. It ensures that the inventory level does not fall below this threshold.

- Maximum quantity

This indicates the maximum allowable quantity in the inventory unit. It sets an upper limit to the inventory level.

Understanding full and partial visibility of catch weight items

The dimension configuration and weight that you set up for a catch weight product determines whether the item uses full or partial visibility.

Full visibility of catch weight items

What does it mean?

You know the exact weight of each individual item. Catch weight items that use full visibility require that the inventory quantity is known for each catch weight unit.

How it works?

- Unique identification: Each item (like a box of cherries) has a unique ID, and its exact weight is recorded.

- Example: If you have boxes of cherries and each box must be individually tracked, you will set up each box as a catch weight item with full visibility. This means each box gets a unique serial number, and its weight is recorded individually.

Partial visibility of catch weight items

What does it mean?

You only know the total weight of a group of items, not each individual item’s weight. Catch weight items that use partial visibility require that the inventory quantity is known for batches of items that use a catch weight unit.

How it works?

- Batch identification: You know the total weight for a batch of items, but not the exact weight of each item in the batch.

- Example: If you receive 100 boxes of cherries, each with a nominal weight of 10 kg, you will weigh the entire batch of boxes together. You record the total weight and the number of boxes under one batch number. You don’t track each box’s weight separately, just the total weight for the batch.